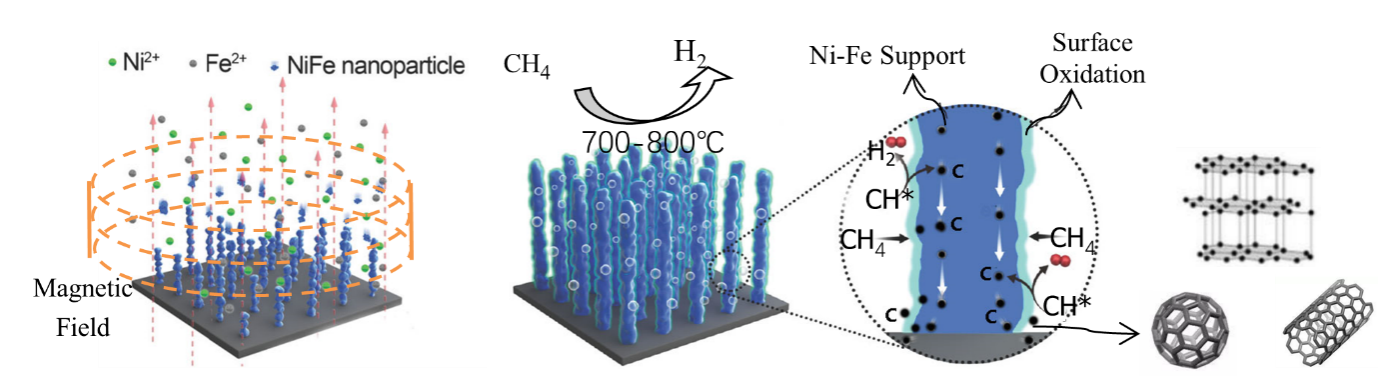

This technology holds promising potential for applications in hydrogen generation and the carbon materials market. The innovative preparation method of the transition metal catalyst system serves as a cornerstone for conceiving, designing, and advancing novel catalyst systems. The successful establishment of a demonstration system for catalytic cracking of methane showcases its capability to produce hydrogen as well as high value by-products of nano carbon materials. This achievement not only offers a theoretical and practical foundation for transforming natural gas into hydrogen through catalytic cracking but also paves the way for industrially applying high-value nano carbon materials.

This technology provides a novel approach to prepare transition metal catalytic systems such as “dual structure functional area” Ni Fe, Ni and Co for hydrogen production by methane cracking. Relationship between catalyst structure, methane conversion and morphology of high-value nano carbon materials is also established. Based on the developed catalyst and study of diffusion-adsorption-desorption process during methane cracking, a high-performance methane cracking rotary reactor for continuous preparation of hydrogen and high-value nano carbon materials is developed.