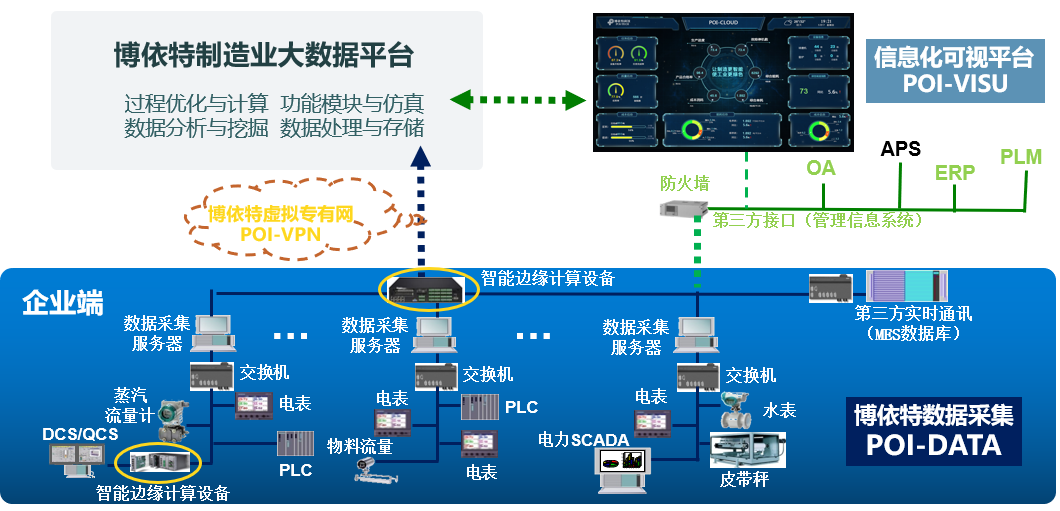

This technology is tailored for process industries, which have traditionally relied on the expertise of experienced employees. It supports sectors such as paper, food, glass, ceramics, cement, and chemical processing by addressing complex challenges that human expertise alone may struggle to resolve. Key focus areas include production planning and scheduling, process transition control, raw material management, quality assurance, equipment operations, and energy optimization.

Drawing on its industry expertise, the project team has integrated industrial mechanisms with AI algorithms to simulate and optimize processes within the process industry. They’ve distilled human knowledge into scalable, replicable models, empowering businesses to enhance decision-making and apply intelligent controls for more stable production.