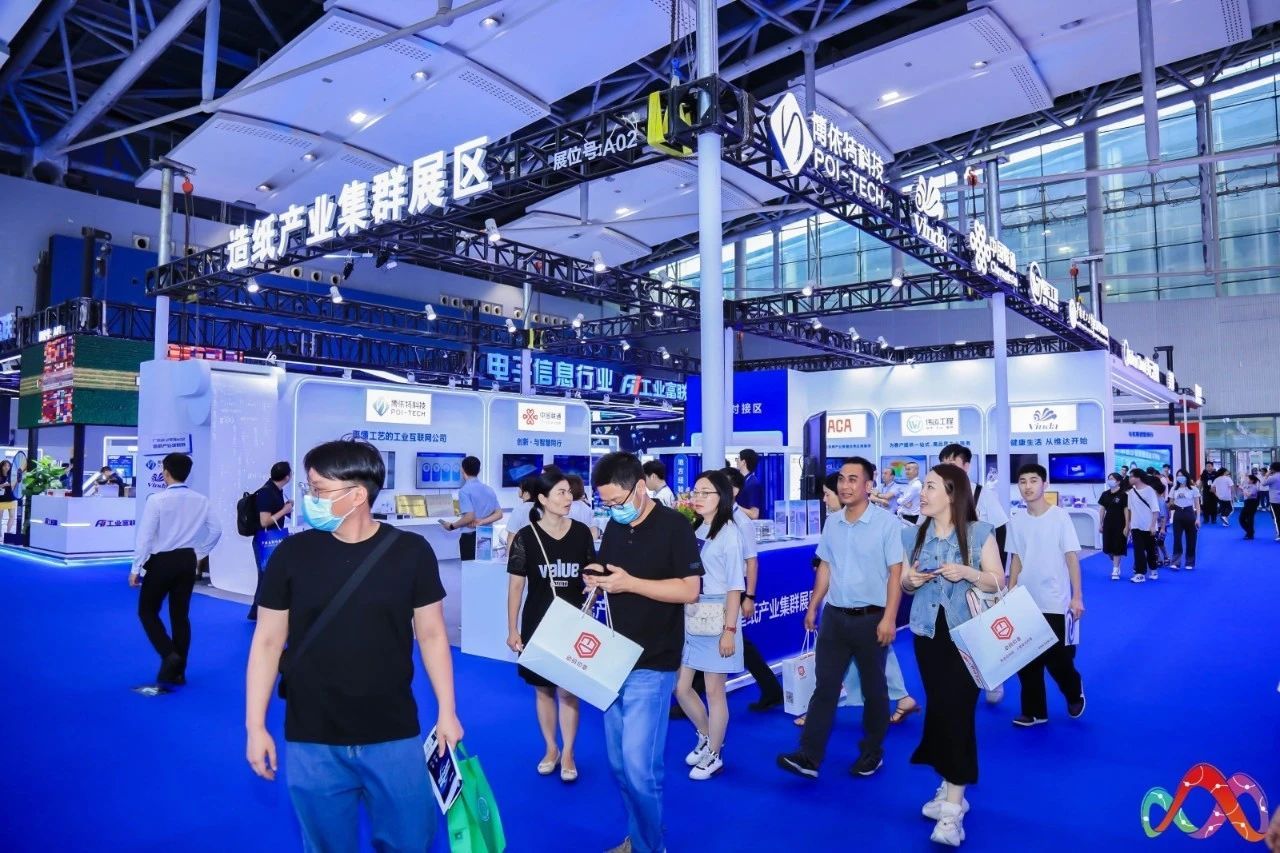

Sponsored by the Ministry of Industry and Information Technology, the State Administration for Market Regulation, and the People's Government of Guangdong Province, the 18th China International Small and Medium Enterprises Fair (CISMEF) took place in Guangzhou from June 27th to 30th. Concurrently, two key events, the "Industrial Internet Exhibition" and the "Small and Medium Enterprises (SMEs) Digital Transformation Forum," highlighted the latest advancements in high-quality manufacturing development powered by digital technology.

In the Industrial Internet section, CSIJRI's POI-TECH and five other exhibitors showcased the digital transformation of the Jiangmen paper manufacturing sector. Ms. Xu Xiaolan, Vice Minister of the Ministry of Industry and Information Technology, and Mr. Sun Zhiyang, Vice Governor of Guangdong Province, delivered speeches at the forum.

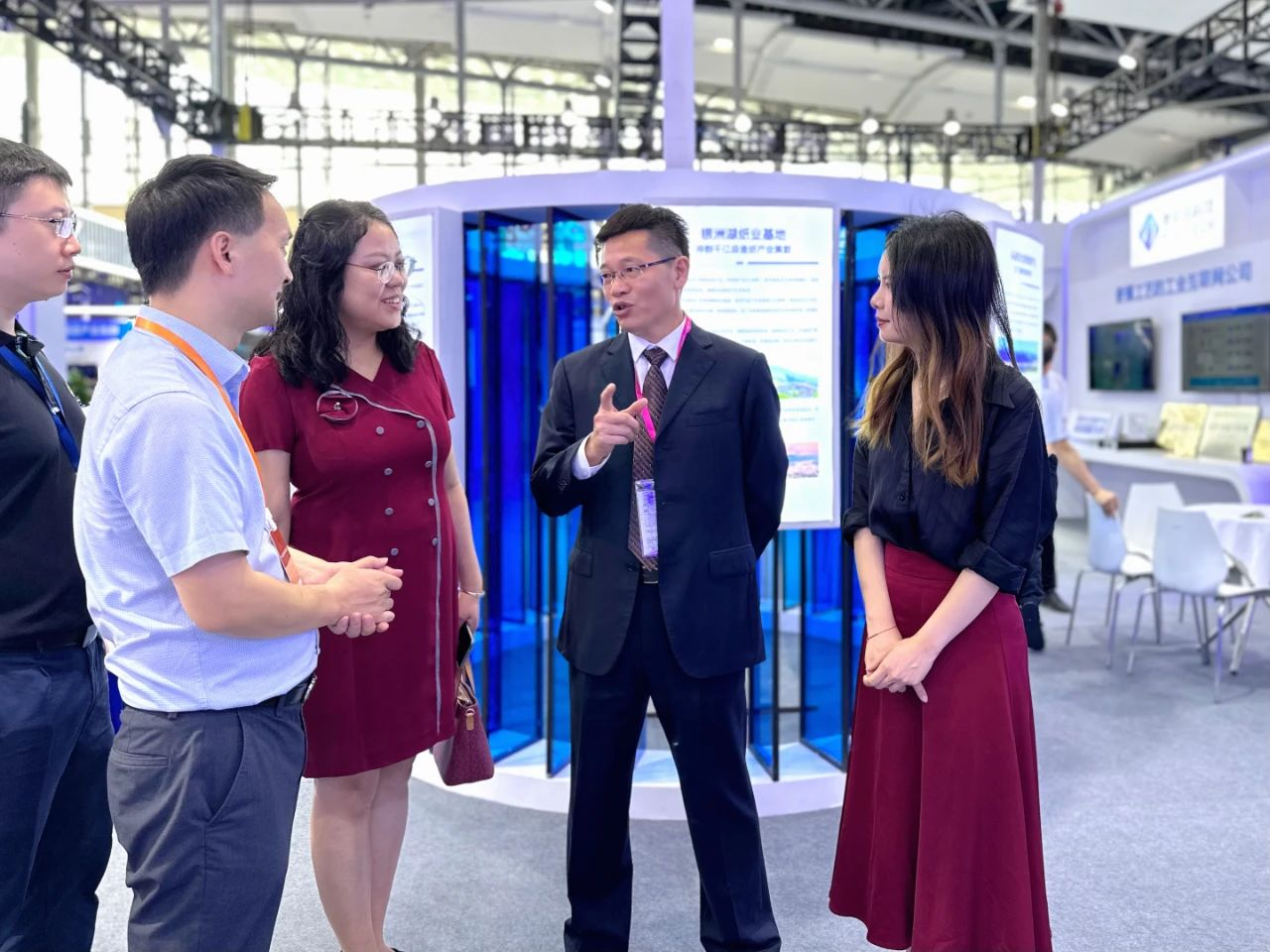

POI-TECH stood as one of the three representative cases of the forum. Dr. Li Jigeng, Chairman and CEO, delivered a keynote speech on "Process AI Empowering Digital Transformation of SMEs and Promoting High-Quality Development of Process Manufacturing."

At the opening ceremony, Dr. Li Jigeng, Chairman of POI-TECH, highlighted that while the process industry can generate large-volume and diverse products, its output value may not be proportionally high. However, it possesses unique advantages in terms of profit margin and competitiveness. Dr Li emphasized the necessity for enterprises in the process industry to collaborate with larger companies to undergo digital transformation and intelligentization, which can be categorized into three stages.

The first stage involves digitalization, aiming at enhancing management efficiency. The second stage focuses on decoupling the relationship between people and production tools through intelligence. Finally, the third stage emphasizes the formation of collaborations between the upstream and downstream of the value chain, building digital industry clusters based on digitalization and intelligence.

The seamless operation of process industries, including paper manufacturing, food processing, building materials, and chemicals, heavily relies on price fluctuations in raw materials, availability of spare parts, and weather conditions. However, the availability of experienced operators, a critical resource, is becoming increasingly scarce. For instance, a paper manufacturing plant with an output value of 3 billion yuan requires over 200 experienced workers for its four-on-three-off shift pattern, incurring a cost of tens of millions of yuan. This poses a significant challenge for SMEs. Hence, there is a pressing need to leverage AI technology to alleviate the financial burden of hiring experienced workers.

Consider the Advanced Planning and Scheduling (APS) in the paper industry. With the growing demand for small and multiple batches, companies often grapple with high product switch costs, challenges in meeting delivery deadlines, low efficiency in manual scheduling, and unclear production material requirements. Enter POI-TECH’s intelligent production scheduling AI model, designed to automatically recommend optimal production schedules and seamlessly switch between different varieties with a single click. Compared to manual production scheduling, this model can slash switching costs by 20% and boost production scheduling efficiency by a staggering 90%. In the 14g base paper production, POI-TECH can help save an average of 1.1% of fiber, translating to approximately 1.4 million yuan in savings per line per year.

The Digital Industrial Chain Emerges as the Key to Breaking the Deadlock.

Enterprise digital transformation is a complex, systematic project and a prevailing social trend. Nevertheless, SMEs often face the dilemma of being "unwilling to transform, unable to transform, and afraid to transform." To surmount this challenge, they must rely on their industry clusters and seek support from larger enterprises to achieve digital and intelligent transformation and upgrading.

This time, POI-TECH collaborated with five partners—Vinda Paper, China Unicom Jiangmen Branch, Jiangmen Weiyun Mechanical and Electrical Automation Engineering Co., Ltd., the School of Light Industry Science and Engineering of SCUT, and Xinhua Glue Silk Factory Co., Ltd. Together, they showcased the pilot application of industry digital transformation for the Jiangmen Paper Industry Cluster, leveraging POI-TECH's advanced process AI.

The Digital Industrial Chain Emerges as the Key to Breaking the Deadlock

Enterprise digital transformation is a complex and systematic endeavor, and it has become a prevailing social trend. However, SMEs often struggle with being "unwilling to transform, unable to transform, and afraid to transform." To overcome this challenge, they must rely on their industry clusters and seek support from larger enterprises to facilitate digital and intelligent transformation and upgrades.

In response, POI-TECH partnered with five key collaborators—Vinda Paper, China Unicom Jiangmen Branch, Jiangmen Weiyun Mechanical and Electrical Automation Engineering Co., Ltd., the School of Light Industry Science and Engineering of SCUT, and Xinhua Glue Silk Factory Co., Ltd. Together, they demonstrated the pilot application of digital transformation for the Jiangmen Paper Industry Cluster, powered by POI-TECH's cutting-edge process AI technology.

As part of the digital transformation of the Jiangmen Paper Manufacturing Cluster, Vinda Paper successfully integrated with its upstream and downstream partners. Following this integration, some companies saw an annual output increase of 4.95%, improved energy utilization rates, a 28.66% reduction in product unit consumption, and an impressive 36.19% decrease in energy consumption.

Digital transformation can significantly enhance operational efficiency, reduce costs, and help SMEs stay aligned with the evolving digital economy trends. It provides fresh momentum for their development and helps resolve their challenges. As one of the first digital transformation pilots to receive central government subsidies, POI-TECH will continue to use process AI technology, strengthen its innovation capabilities, and drive high-quality development in the process industry.